Top Guidelines Of Spandrel Glazing

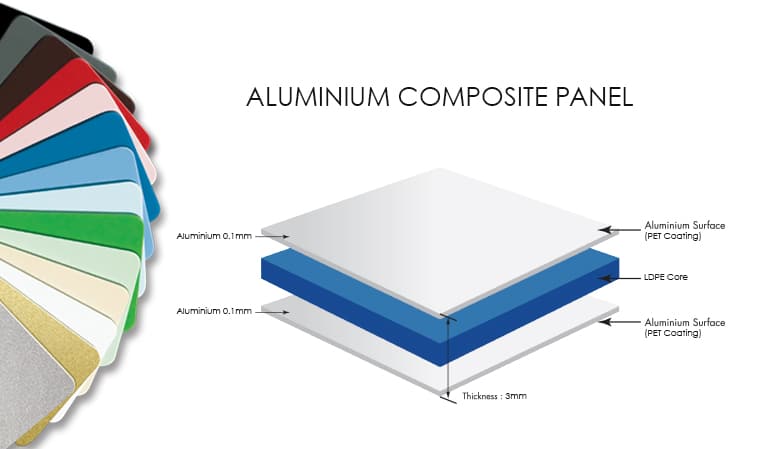

Building and construction site panel constructed from aluminium composite product (Dibond) Detail view of building site panel Aluminium composite panels (ACP), made of aluminium composite product (ACM), are flat panels containing two thin coil-coated aluminium sheets bonded to a non-aluminium core. ACPs are frequently utilized for exterior cladding or facades of structures, insulation, and signs. ACP is mainly utilized for exterior as well as inner architectural cladding or dividers, false ceilings, signage, machine coverings, container construction, and so on. Applications of ACP are not restricted to outside structure cladding, however can additionally be utilized in any kind of form of cladding such as dividers, incorrect ceilings, etc.

ACP has been utilized as a light-weight yet very durable product in construction, particularly for transient frameworks like trade convention booths as well as comparable temporary elements. It has lately additionally been adopted as a backing product for mounting art digital photography, frequently with an acrylic finish using processes like Diasec or other face-mounting techniques. ACP material has actually been made use of in renowned frameworks as Spacecraf Planet, Van, Dusen Botanical Yard, the Leipzig branch of the German National Collection. These frameworks made ideal usage of ACP with its expense, resilience, and efficiency. Its flexibility, low weight, and simple developing as well as refining enable ingenious style with raised strength as well as durability (spandrel glazing).

The common ACP core is polyethylene (PE) or polyurethane (PU). These materials do not have good fireproof (FR) buildings unless specially dealt with as well as are for that reason not generally ideal as a structure material for residences; a number of jurisdictions have actually prohibited their use entirely. Arconic, proprietor of the Reynobond brand, warns the potential customer. Worrying the core, it says that range of the panel from the ground is a factor of "which products are much safer to use". In a sales brochure it has a graphic of a building in fires, with the subtitle" [a] s soon as the structure is more than the firemens' ladders, it needs to be conceived with a fireproof material".

70% mineral core) from there to as much as c. 30 meters, the elevation of the ladder; and also the European A2-rated item (c. 90% mineral core) for anything above that (spandrel glazing). In this brochure, Fire Safety and security in Skyscraper: Our Fire Solutions, product specification is just provided for the last 2 products. The cladding materials, particularly the core, have actually been linked as a feasible contributing element in the 2017 Grenfell Tower fire in London, in addition to in skyscraper fires in Melbourne, Australia; France; the United Arab Emirates; South Korea; and the USA. Fire-rated cores, such as mineral wool (MW), are a choice, yet are normally a lot more costly as well as frequently not a lawful requirement.

Top Guidelines Of Spandrel Glazing

Aluminium can be painted in any type of sort of colour, as well as ACPs are produced in a vast array of metal and also non-metallic colours in addition to patterns that imitate other products, such as wood or marble. The core is generally low-density polyethylene (PE), or a mix of low-density polyethylene and mineral product to show fire resistant homes. 3A Compounds (previously Alcan these details Composites & Alusuisse) created aluminium composites in 1964 - as a joint invention with BASF- and industrial production of Alucobond began in 1969. The item was patented in 1971, a patent which ended in 1991. After the expiry of the patent straight from the source a number of companies started business production such as Reynobond (1991 ), Alpolic (Mitsubishi Chemicals, 1995), etalbond (1995 ).

05 W/( m, K) for mineral wool. Consequently, they can accomplish various U-values relying on the core as well as the thickness of the panel. The installation of a system with sandwich panels decreases thermal bridges with the joints. The assessed sound decrease measurement lies at approx. 25 d, B for PU aspects and also at approx. 30 d, B for MW aspects. The room in between the supports can be up to 11 m (wall surfaces), depending on the kind of panel utilized. Typical applications have spaces in between this content the supports that are approx. 3 m 5 m. The thickness of panels is from 40 mm approximately more than 200 mm.